About Us

Trust the water experts. For nearly 150 years, A. O. Smith has been committed to delivering innovative solutions that bring comfort to your home and business.

About A. O. Smith

For millions of consumers, business owners, property managers and engineers worldwide, A. O. Smith has delivered innovative hot water solutions for over 80 years.

A. O. Smith’s selection of residential and commercial water heaters, boilers, and storage tanks is unmatched for quality and diversity. Anywhere hot water is needed, A. O. Smith can provide an energy-efficient solution with maximum value during and for years after installation. And, A. O. Smith stands behind its products and its customers with world-class service, combining cutting-edge technology with committed people who take pride in being the very best.

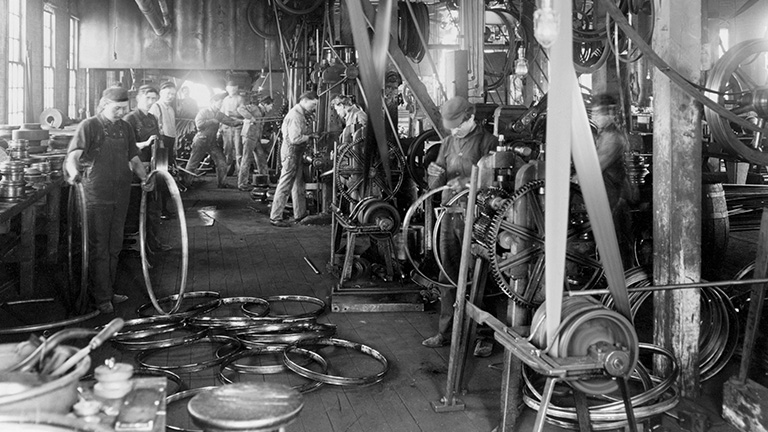

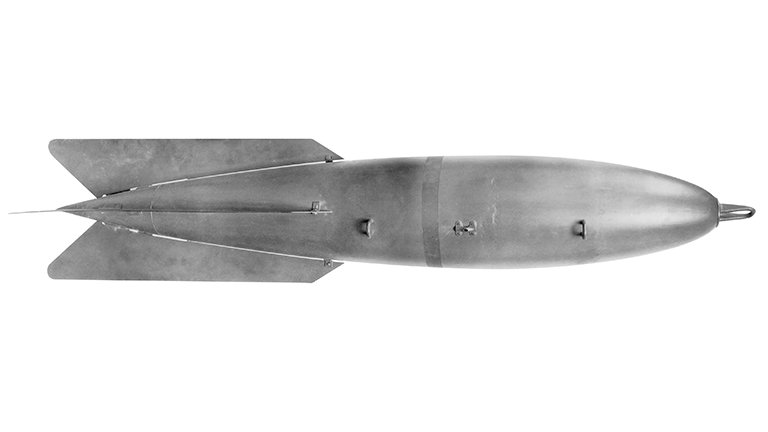

A. O. Smith produced its first residential water heater in 1939, establishing a tradition of innovation that continues to this day. In 1953, A. O. Smith shipped its first commercial water heater equipped with a “glass-lined" tank, which remains the industry standard for protecting steel from the corrosive effects of water.

In 2004, A. O. Smith reaffirmed its mastery of glass lining technology by introducing patented Blue Diamond™ glass coating on its best Conservationist® residential water heaters. Blue Diamond™ provides the ultimate protection… over twice the corrosion resistance compared to industry-standard glass lining.

The Cyclone® Xi water heater symbolizes A. O. Smith’s clear leadership in the commercial water heating market. Introduced in 1997, The Cyclone® HE commercial gas water heaters were designed with high thermal efficiencies to deliver maximum hot water output at the lowest possible cost, which can translate into thousands of dollars saved per year for owners of restaurants and other commercial buildings.

In 2010, A. O. Smith launched a new era in high efficiency products, introducing the hybrid electric heat pump, high efficiency gas, and solar water heating solutions. 2010 also brought about a new partnership with Takagi, leading A. O. Smith to market and manufacture a comprehensive line of tankless products for both commercial and residential applications.

In 2014, A. O. Smith made significant progress in the commercial water heating business with the launch of the Cyclone® MXi. This new generation of the flagship Cyclone technology integrated modulating operation, increasing performance and efficiency. Over the next 5 years, the Cyclone family grew to include the Cyclone® LV and Cyclone® XL models for large volume and high demand applications.

Drawing from its expertise in commercial water heating technology, A. O. Smith launched the ProLine® family of commercial-grade water heaters for the home. This comprehensive line of residential water heaters uses commercial-grade components for increased durability.

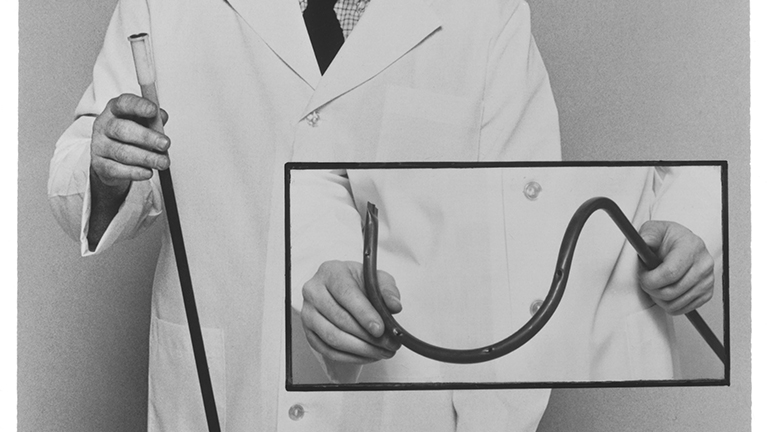

An expert in both water heating and treatment, in 2022, A. O. Smith combined both of those technologies to introduce X3® Scale Prevention Technology. This first of its kind technology improves our existing suite of condensing tankless products by preventing scale buildup and eliminating the need for descaling maintenance. With this achievement, A. O. Smith introduced the industry’s first ever “Peace of Mind" 15-year limited warranty covering scale-related failures, and continuing the company’s long-standing history of industry-defining innovation.

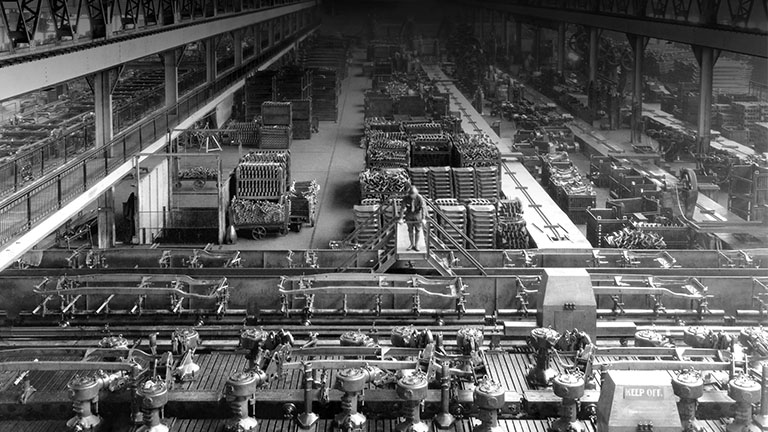

A. O. Smith Water Products Company is headquartered in Ashland City, Tennessee, home of the world’s largest water heater factory. The A. O. Smith network includes five manufacturing facilities in North America, plus plants in Nanjing, China and Veldhoven, The Netherlands.

Learn More About Us

Newsroom

Careers

Awards & Recognition

Global Facilities

A History of Innovation Timeline

A. O. Smith and Takagi enter into a joint venture to market and manufacture a comprehensive line of residential and commercial tankless products in North America

Why A. O. Smith?

A. O. Smith is a leading manufacturer of both residential and commercial water heating technologies, including the #1 most specified commercial water heater.

For more than 145 years, we’ve developed state-of-the art products that push new boundaries and improve the lives of our customers.

We combine cutting-edge technology with committed people who take pride in providing the very best support for our customers.

Our products are put through rigorous quality and endurance testing so now matter where hot water is needed, A. O. Smith can provide a solution you can count on.